Bending Basics

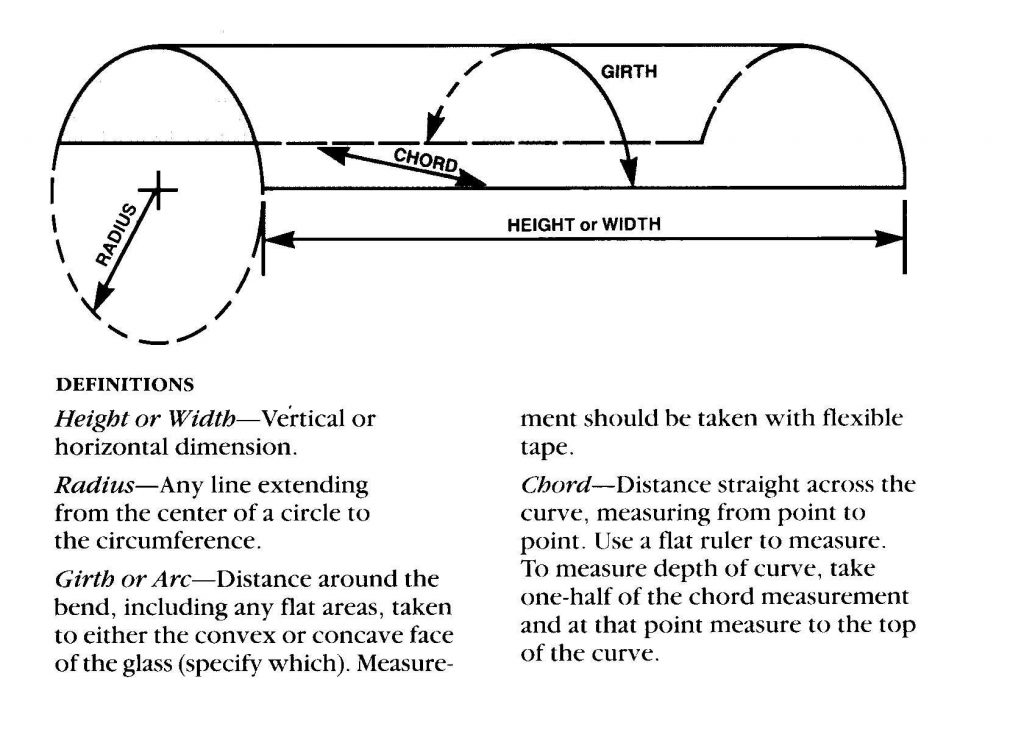

Unlike the length and width dimensions required to order a piece of flat glass, the fabrication of curved glass requires precise dimensions of the shape of the glass. There are two ways to describe the shape. The first consists of the girth, height or width, and radius dimensions. When the radius is not known, the chord and depth dimensions can be provided. A flexible tape measure is needed to measure the outside girth. A flat measurement is used to measure the height/width, inside chord, and inside depth. A hardboard or mylar template is required with all the dimensions noted above if an accurate radius dimension cannot be provided.

Bent Glass Manufacturing

Various types of steel molds are used for slumping the flat glass into desired shapes. Glass is placed on top of a pre-heated mold and then placed into a kiln. At about 600 °C, the glass begins to melt and bend, melding into the shape of the mold. The kiln is very slowly cooled down, completing the bending glass. In some cases, two or more pieces of glass are bent at the same time to ensure high quality laminating and insulating following the bending process.

Edgework

The following edge finishes are available: Seamed, Ground (pencil polish), Flat ground (ground with chamfer), and Flat polished (polished with chamfer)

Shapes

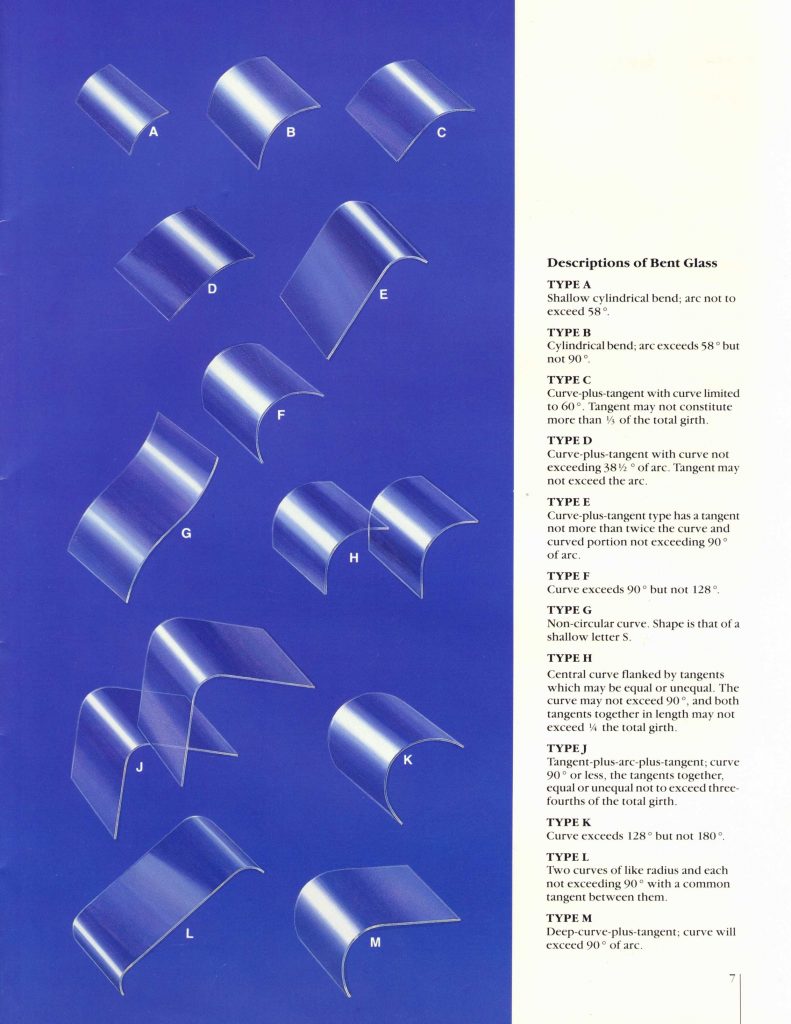

The illustration below shows different shapes that are available.

Glass Options

Clear and low iron glass, tinted glass, Low-E coatings, patterned glass

Safety and Thermal Performance Glass Options

Laminated Glass, Insulating Glass, and Laminated, Chemically Strengthened Glass and Tempered Glass

Additional Fabrication

Hole drilling is available. Interior notches can be pattern cut. Complex shapes are accomplished via waterjet cutting.

Standards

ASTM C1464-16 Standard Specification for Bent Glass